APAC-Central, Inc., an Oldcastle Company, is an industry leader providing materials including aggregate, asphalt, sand, stone, ready-mix concrete, and high-quality pavement construction and services.

David Lloyd is a Mine Planning Engineer at APAC-Central, responsible for operations at 30 locations across Arkansas, Oklahoma, Missouri and Kansas. David’s team uses Kespry for inventory, mine planning and ad-hoc projects, flying more than 500 flights in 2 years, to collect fast and consistent data across all operations.

Mine Planning and Progress Tracking

When David joined APAC, the company had acquired several sites that were under the APAC brand, but operating independently. He needed to find a way to manage the operations as a unified company. David found Kespry to be an ideal solution to quickly build 3D models and generate highly accurate topographical outputs unique to each operation. All collected data is consistent and available in the Kespry Cloud providing a unified view to everyone in the APAC business.

“Kespry allows us to get more rapid and consistent data. Scheduling quarterly updates for 25-30 operations was not a feasible idea with prior technology to get this kind of data in this kind of timeframe.”

-David Lloyd, APAC-Central, Inc

Inventory Management

David’s team uses Kespry for fast, safe, and accurate inventory management. In 2 years, David operated 520 flights measuring 612 stockpiles and mapping 17.8k acres. He compares how APAC used to perform inventory surveys before Kespry. “It used to take three to five people involved in an operation to get decent survey data, and it would often take hours and hours. Now it’s one person and thirty minutes, for better data.” David explains, “Walking the piles was a necessary evil, and involves climbing on top of stockpiles on foot, which is not the safest action… Our technology has really made our lives easier. It’s made everything a lot safer and we’re getting a lot better and more consistent data as we’ve improved our systems.”

Waste Rock Material Management

Kespry enables APAC to measure volumes for storage and waste management. Mining companies need to analyze the topography of a location to determine how many reserves they have left and how much material they can store. Materials are rarely at surface level, so site operators need to strip, remove and store excess overburden.

Fill Storage

An additional complexity is in working with a landfill because permitting requires active monitoring of airspace volumes. Kespry Cloud Software allows APAC to measure volume on surfaces to determine how much storage is available and how much airspace is left to remain compliant within the terms of the permit.

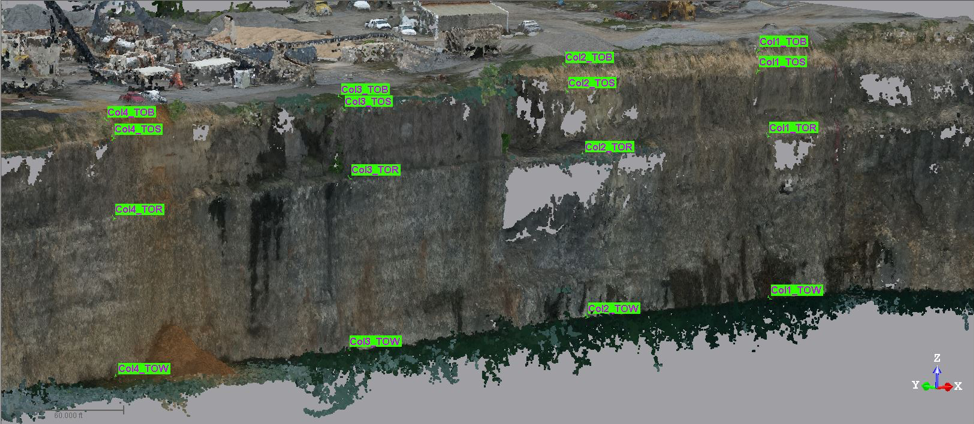

Analyzing Reserves – An Alternative to Core Sampling

David’s team is finding innovative applications for their Kespry system. APAC wanted to calculate reserves in an inactive pit to determine if it was worth the cost to work that site again. In the past, they would need to hire a core-drilling crew, drill holes, hire geologists to log the holes, convert data, and then generate a model for the analysis. The process would have taken 2 weeks and more than $10,000. Instead, David used his Kespry Drone to fly the high wall at the site, picking up geologic data in a 3D Point Cloud, to acquire the same information. The flight process took just one hour onsite, and in a couple hours in the office with his data in the Kespry Cloud, David was able to produce a geologic model and core sample.

Communication and Accessibility to Information

A significant benefit of the Kespry Cloud solution is increased communication and accessibility to data at APAC. The Kespry Cloud empowers anyone in the company to have access to the same information. David says, “Operational stakeholders don’t need to wait for specific outputs. They are able to see the data and perform calculations. Before, stakeholders couldn’t see where the data was coming from and now we have a tool to share so that they can make their own calculations and then come to the meeting asking about a model.”

Software Integration

The Kespry Cloud enables users to export data into any geospatial software, so David is able to integrate data with systems that APAC was already using. David notes that the Kespry Cloud interface is easy to use and the seamless information transfer allows him to export data from the Kespry Cloud to their existing mine planning software suite, specifically to Trimble RealWorks and Maptek I-Site.

Speed and Accuracy

Before Kespry, APAC used a ground based LiDAR system and developed inventory with point cloud data. To test accuracy of the drone, David’s team measured stockpiles with both the Kespry Drone and the LiDAR system and found that the volume measurements were equal in both methods, but significantly faster with Kespry. After proving value with their first Kespry Drone, APAC increased their fleet to add a Kespry Drone 2s, which includes the PPK system. David comments, “The PPK system allowed us to be more accurate without doing ground control, which saves us a lot of time. The system is faster and more consistent to set up the same flight each time for consistent results.”

“People are surprised that I can get the data so quickly. I really prefer where we are compared to where we were. Kespry made data acquisition a lot easier, I can spend more time on modeling than out on the field collecting.”

-David Lloyd, APAC-Central, Inc.

Future

David recommends Kespry for the significant time savings, improved data consistency, and communication that he experienced at APAC. David says, “I’m confident in the data. We’re getting the accuracy that we need and it’s making things a lot easier and faster. It’s the way we’re going. It’s the way of the future.”

Watch the Webinar Using Drone Data for Mine Planning to hear from David about how APAC-Central uses Kespry for fast, safe, and consistent mine planning.