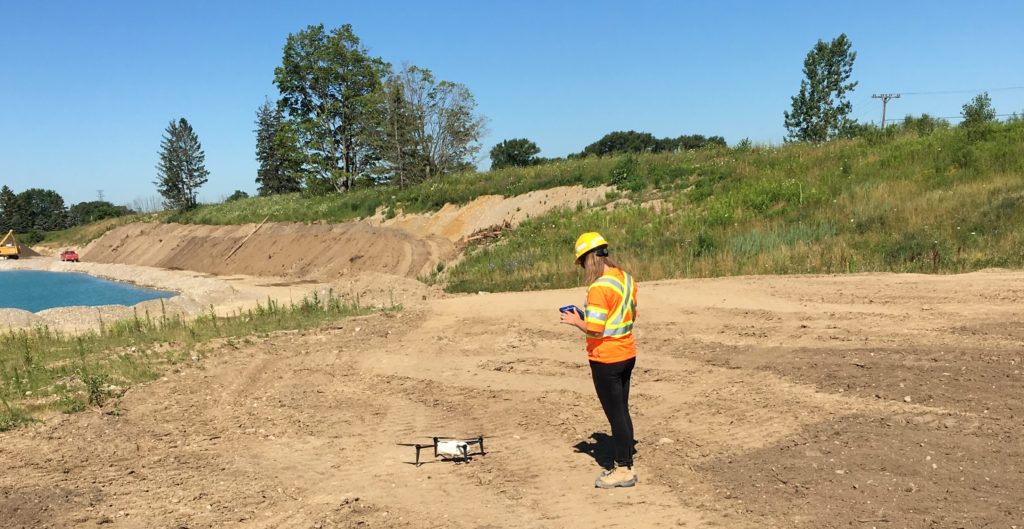

Votorantim Cimentos is one of the largest cement manufacturers in the world, with global companies including St Marys Cement and Canada Building Materials (CBM) in North America. Jennifer Bernard is the Land and Resource Coordinator for the Aggregates division of CBM, and its lead drone pilot.

We had the opportunity to talk with Jen about her work and experience with Kespry.

Jen: I work in the Aggregate Division, where we use Kespry imagery to help us with mine planning. We track earthwork movement, like stripping to see how much volume has been extracted, and placed into rehabilitation. We also work at a couple of our cement business sites and they have expressed interest in using the drone imagery to help them with planning and provide more accurate measurements. Even though we generate big files, the processing time has been awesome. It’s been a great tool.

How is flying Kespry better than hiring surveyors for mine planning?

Jen: We want to use the drone to save time and costs instead of always relying solely on hiring third party surveyors. Hiring surveyors can introduce an additional safety risk as well depending on the methods they use for measuring stockpiles for instance. Having me operate the drone on site has increased benefits because I know most of the sites pretty well. It’s safer because I know the changing conditions, whereas outside parties have to do an orientation every time they come to site, and figure out what’s changed since they’d been there last.

Why did CBM choose Kespry?

Jen: We chose Kespry because the system was so efficient at providing the information and the capabilities that we were looking for. A big factor was that the Kespry Cloud supports the background data processing. It would have taken a lot of training if we had to get the images and then process them all ourselves, so the fact that Kespry has the Kespry Cloud and we don’t have to do the back end processing is great. That was one of the major factors of why we went with Kespry over other companies. We’ve had great success this year. It’s been a great experience.

How are you using Kespry in your work?

Jen: For the past year or so, I’ve been collecting views of entire sites, going out and doing full site images. It’s been really effective because we can do some of our larger aggregates sites all in one day and not have to have that picture in multiple, separate images that we then have to worry about stitching together over different time periods. We use those for mine planning and rehab planning which we do for each of our active sites every year. We outline what we extracted last year and what we want to extract this year. The plan includes stripping and rehab. I typically fly the drone before stripping, after stripping, and then again for rehab.

Can you tell me more about your rehabilitation planning projects?

Jen: In the last couple of years, the aggregate industry in Ontario has had a big push to have progressive rehabilitation completed on active sites in order to demonstrate to the public that we are interim land users and good stewards of the land in which we operate. This aligns with our own company goal to leave the land in as-good-as, or even-better condition. Most of the site plans in the Province have that requirement, so that when we’re opening up phase two or phase three, for instance, phase one is getting rehabbed. As a result, the maximum disturbed area is smaller.

Rehabbing progressively is an excellent approach because if we’re doing specialized rehab projects, like restoration of the land to productive agriculture, it’s really important not to store soil for a long period of time because all of the good microbes start to die off; and, as a result the topsoil and subsoil loses its fertility. It’s good to be able to put the soil right back into rehab because it maximizes the potential for future productivity of the soil while reducing costs for us by having to only handle the soil once, so it’s a win-win. That’s one of the reasons why we started doing more accurate and precise mine planning so we can make sure that that stripping is always going into rehab.

How is Kespry helping you with that rehab work?

Jen: Kespry is helping us because Google Earth and other online imagery doesn’t provide up-to-date images; but, they were the only tools we had before we had the drone. We can literally do rehab, wait until it greens up, and when we go out to fly we have an up-to-date picture the next day, so it’s really efficient. With Kespry, because the resolution is so good, you can just zoom in and get a nice picture of the overall area. Then we can measure the area, as well as the amount of rehab that we completed. That’s great because we also have to report that to regulatory agencies, so having that degree of accuracy has really helped us quantify our disturbed and rehab areas more accurately. We can also look at the sloping, assess the gradation and see if all of the seed took, and if there is a need to touch up any areas, so it’s also really useful for that.

We also use the drone images when we apply for progressive rehabilitation awards at our industry association, to show how well the rehab has taken.

Have you discovered other projects that you weren’t originally expecting to apply Kespry in your work?

Jen: One unique project we’ve been doing is using it for our safety program for traffic maps to make sure that trucks and anyone entering the pit have an updated image of where to go in case stockpiles locations have shifted as a result of processing and shipping over time. We put the image right in our traffic management plan, so that’s been really helpful. In Ontario, the Ministry of Labour (MOL), now requires every site to have a detailed traffic map, so we’ve been transitioning all of ours to the drone images because they’re such high resolution and it’s so easy to see everything. Once the image is available, I can download it right away. That’s one of the really easy things I’ve found about using the Kespry Cloud. It’s a lot simpler for us to be able to control the data.

Have you discovered any other benefits using Kespry that you were not originally planning for?

Jen: Kespry also helps us save money on our tax assessments. In the Aggregates business, our tax is classified as industrial, but if we can produce an image and outline the areas that are not in production, say they’re rehabbed or they’re not extracted yet, the land is assessed at a lower tax rate. So it really benefits us to be able to get a snapshot of the entire site when we get the request form and outline the exact areas of the different land classifications. Then using Kespry and Google Earth, we can get the exact measurement of any disturbed areas for instance, or conversely how much rehab we have completed. We get tax breaks on that, so instead of paying industrial tax on our whole entire site, we can justify a tax break on certain areas that are rehabbed or haven’t been opened yet. It actually ends up saving a lot of money in the long run. It’s something we started using the drone for last year, and it’s been really beneficial.

What made you interested in mining and aggregates?

Jen: I went to school for Ecology and I did my master’s at the University of Guelph, so I have a background in science. I applied for this job through University recruiting and thought “Wow, this is super interesting.” I think aggregates companies and drone companies could do a better job letting students know about this career path. I’ve really enjoyed my job so far, and especially the drone aspect.

What else do you love about your job?

Jen: What I really love about my job is that every day is different. There’s so much to learn. I’ll have office days in the winter; but in the summer, it’s full force ahead and I’m always flying around the different sites, so it’s nice if you like to be outdoors and interact with people and nature. I love the fact that I can go to one of our sites, fly the drone and then look at the data the same day and use it to work on mine and rehabilitation planning.