An interview with Tony Manatt, Owner and President, and Rob Manatt, Project Manager, at Wendling Quarries

Manatt’s Inc. is an industry-leading heavy construction company that started in 1947 with the purchase of a single Studebaker truck and is still family owned and operated. The company has grown to include all facets of road construction including sand, stone, and gravel divisions. Acquired in 1987, Wendling Quarries is the largest subsidiary of Manatt’s Inc. Under the leadership of Owner and President Tony Manatt, Wendling Quarries has grown over fourfold since joining the Manatt Family of Businesses. Rob Manatt is a project manager who maintains the relationship between Wendling and Kespry. As a large operation, serving customers in many locations, it is critical for the company to have a current and accurate view of inventory and reserves needed to run the business.

Why is inventory management critical for your business?

Tony: I quickly learned in our fast growth that it was really important to know how many tons of reserves we had available to us, or already stripped and ready to go in inventory. We’re trying to find the best ways to manage inventory because that’s our money in the bank when we put up aggregate piles.

Including our partners, we probably run around 15 portable crushers across about 200 quarries. We need to plan inventory to get those crushers to put up piles to meet the needs of all of our customers. At Wendling Quarries alone, we have over 40 quarries and 11 sandpits in 13 counties throughout Eastern Iowa and Western Illinois. We service those sites with seven crushing plants, eight wash plants, and two sand dredges. The majority of our plants are portable, and we move them several times per season. Many of our sales tons are tied to construction projects, so it’s important to be accurate as we’re building aggregate piles for an asphalt or concrete paving project that’s been let through the DOT.

How did you manage inventory before Kespry?

Tony: I hated the whole process of inventory. It was always inaccurate, and it was always an issue to put together a team that would take care of inventory. In a couple days of surveying, we would need to measure anywhere from one to two hundred irregular, frozen, snow-covered piles. It couldn’t be done. I’m that guy that climbed those frozen stockpiles. I’m that guy that stood out on that ledge to try to hold a pole while somebody surveyed it. I’m that guy that rode around in that car with the chain-smoking auditor with windows that wouldn’t roll down. Then to bring that much old survey information together and calculate it turned into a daunting task. I was ready for a better way.

What other inventory solutions did you try before Kespry?

Tony: We tried LiDAR technology with a gyrocopter. I rented planes and flew some quarries, trying to come up with some efficiency and accuracy to figure out the best way to survey these piles. Estimating wrong makes a big difference in year-end profit.

One of our other companies bought a drone. The battery packs were endless. It was manually run, so it was always involved in accidents and often broken. Only one person was trained to fly it and he was plagued by not having the newest technology. Cameras were outdated and the imagery was not good. The computing power needed for downloading the information took every bit of the computer systems available, so he would have to wait until evenings and weekends to download that data into our servers, and then use various data applications to put it into survey information that management could understand. And even then, the accuracy was always in question.

I had been through different survey software and hardware depending on who was the head of survey. We’ve had guys use different systems including Total Station and GPS, but people move jobs. A change in personnel would leave with all that knowledge towards whatever technology he sold me on. As the owner, I hated that. That’s why I love the simplicity of the Kespry system. I could have three guys that know how to run it so that if somebody leaves, I don’t have technology sitting on the shelf that I can’t use. That was a very attractive aspect for Kespry. Its simplicity, the lack of joysticks. It was so cool to program the coordinates on an iPad. It takes off, it does its thing, it comes back.

Why did you choose Kespry?

Tony: We had a lot of piles to inventory. Rob Manatt saw the potential of using drones as survey equipment and with our quarry development. Rob recommended Kespry for the ease of use and data in the cloud. With frequent technology changes, I love the fact that we’d lease and get technology updates along with the use of the drone for survey.

When Rob proposed Kespry, I liked the ability to upgrade through a lease. If there’s an issue, it’s insured, and we’ll have another one in the mail the next week. I liked the simplicity of flying it and downloading data the same day, that it is iPad-based with no joystick. And especially that I didn’t have only one guy who was the only guy to know how to fly it. I want the numbers. I just want accuracy and I want them now, and I want them no matter who’s sick today.

What other projects have you found to apply the Kespry System?

Tony: We’re using Kespry in pre-production and then in production, and then post-production for inventory. We use it in the closing of a quarry as well, in the reclamation to know what we’ve got to do to meet the bonding required to put things back and look good.

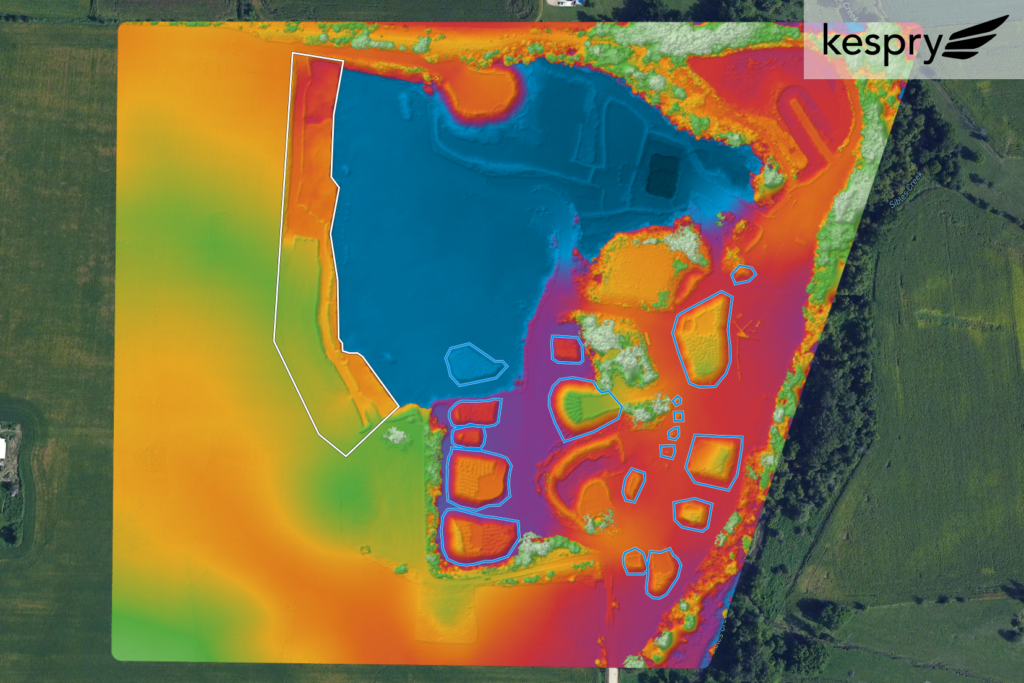

On the production side, we’re surveying our ledges. Instead of sending a survey crew out to understand how much reserve we have in the bottom stone ledge at a quarry, we’ll use the drone. We use it on the planning side to know inventory of bank tons available. Our quarry development team can come to a meeting, pull up some survey work and know if we’ve got the ledge available to meet the salespeople’s needs.

On our hired contract stripping, we’ll use Kespry for payment periods. We’ll compare the starting measurements with load counts and some volumes that we’ve measured, so we’re becoming very accurate in our methods of payments to our hired dirt-moving crews.

How do you use the Kespry 2s Drone?

Rob: We always tie in to a base point when we survey with the drone. We’re utilizing that base system on every flight because we want as much accuracy as we can get. Specifically that’s helpful on the pre-strip and post-strip projects, where we hired a dirt moving contractor and they’re using their own methods, whether it’s counting the loads, or their own GPS surveys to calculate how much volume of dirt they’ve moved, and we’re using the drone. It gives both us and them a sense of confidence knowing that we’re using that PPK system and we’re within the centimeter accurate on our volume calculations.

We’re using PPK for every flight. We might use a flight to do multiple projects. We’ll cover a 150 to 200-acre site and use that same flight to do our inventory survey and also maybe regrade a road, build a ramp, work with our hired stripping crews, calculate reserve bank tons. We have multiple bench sites and we rely on that 2s system to give us accurate information about how many tons we have available to crush in a particular ledge. If we’re having drainage issues in the bottom of a quarry, we’ve used the 2s system to look at how we can carve a channel or just push some dirt around to try to get water drained in the places where we need it to go.

We just put a new sump in one of our quarries, the sump being the hole in the bottom of the quarry where the water drains to, and then we pump it out from there. We used our data from Kespry to get accurate information about elevations, and then our pumping expert was able to determine the necessary size of pump and pipe to have everything flowing at the right speed to keep the quarry de-watered and keep our wash plant supplied with fresh water.

How much time do you save using Kespry?

Rob: Before Kespry, we had a handheld system and then we had a stick with a rover. We would walk the base of the pile, collecting points, then walk all over the piles collecting more points, and then put them into AutoCAD and then calculate volume. For a medium to large site, it’d take you all day, or a couple of days, just to do the leg work of walking around and taking the points. Then probably a week to get the information you were looking for, and hours and hours of work. Whereas now, we send somebody out with a drone. They fly anywhere from one to half a dozen sites in one day. We can have all six of those sites inventoried by lunch the next day. In a day and a half, you’ve got six sites covered, where it used to take a week to do one site.

How is your work safer now using Kespry?

Rob: To me, one of the things that really sold me on this Kespry system is the safety aspect, because I was one of those people climbing the piles and walking around. That could be a very dangerous task. Piles might cave off, or if you slip and fall down a 40-foot pile, that’s not going to be good for anybody. Eliminating that safety hazard was huge in terms of what Kespry has provided.

What is your expectation for the future?

Tony: I think there’s going to be more and more drone work. There are all kinds of construction projects that could use drone that would make progress payment surveying safer and more productive. What you’ve got is a classic combination of old industry and new technology. I definitely see the importance in productivity and safety. I am just so impressed with what we can get done nowadays with technology.

Learn more about efficient, safe, and accurate inventory management and mine planning with Kespry